Making a composite box (tray) with burlap

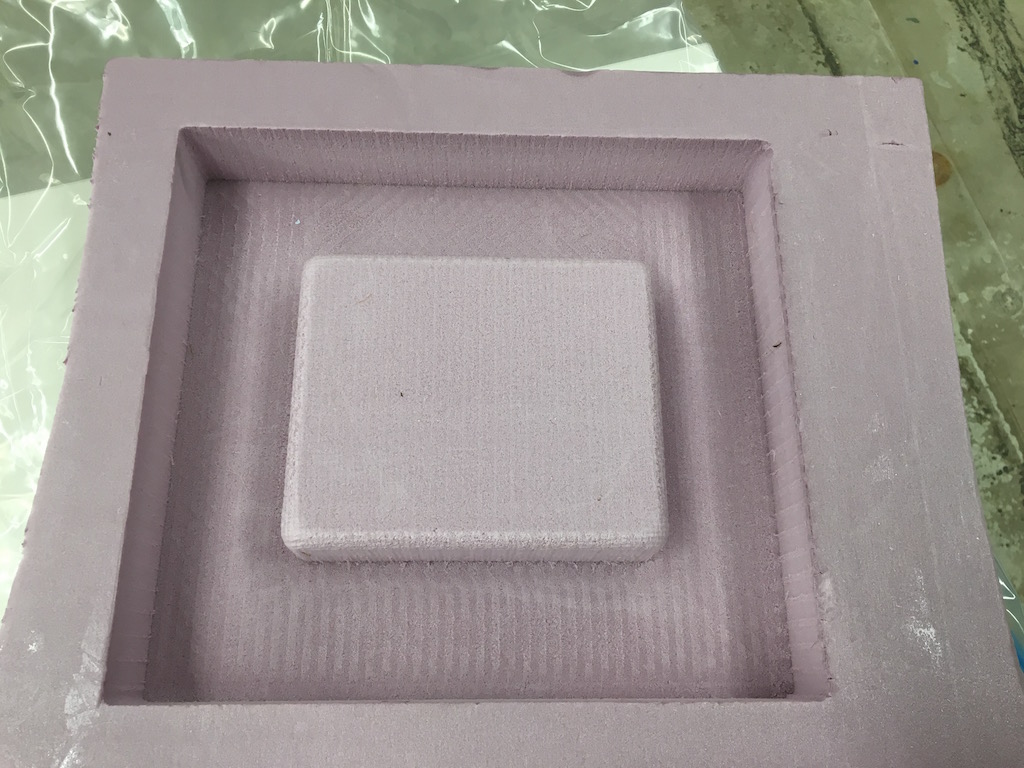

Because composite is not one of the useful tools to make any of my final projects, I decided to just experience it with some simple design. I modeled a box in Solidworks and cutted foam with desktop shopbox (1/4" endmill, 40mm/s feed rate with rough cut).

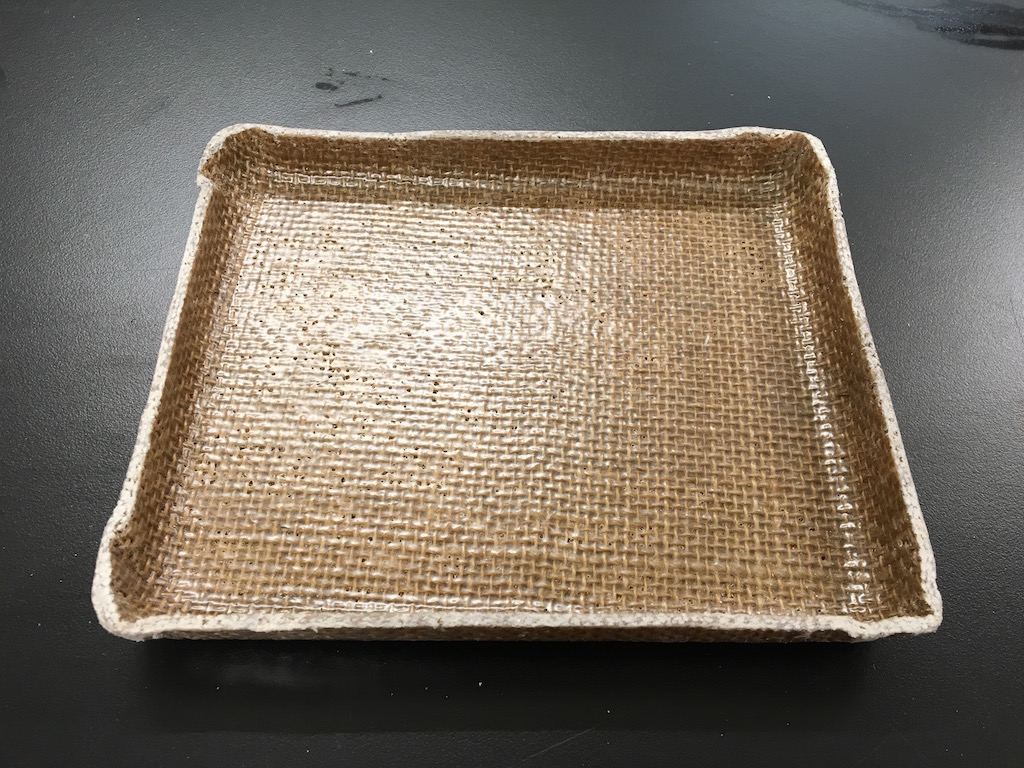

I lay down three layers of burlap with the middle layer texture rotated 45% for additional strengh. The resin is mixed with 2:1 ratio and brushed onto each layer of burlap. The satuated burlap is then encapsulated by plastic sheets and covered with a thin layer of cotton. I tried to conform the mask with the layers by hand as much as possible before it was placed in the vaccum bag. After forming in the vacuum for about 4 hours, I demolded and it was hard dry.

I used a handsaw to cut out the box part. Because of the curvature on the corner, the burlap didn't nicely conform to the box but have many wrinkles. So I decided to cut it very shallow to make it appear nicer. But as the consequence it's more like a tray than a box.

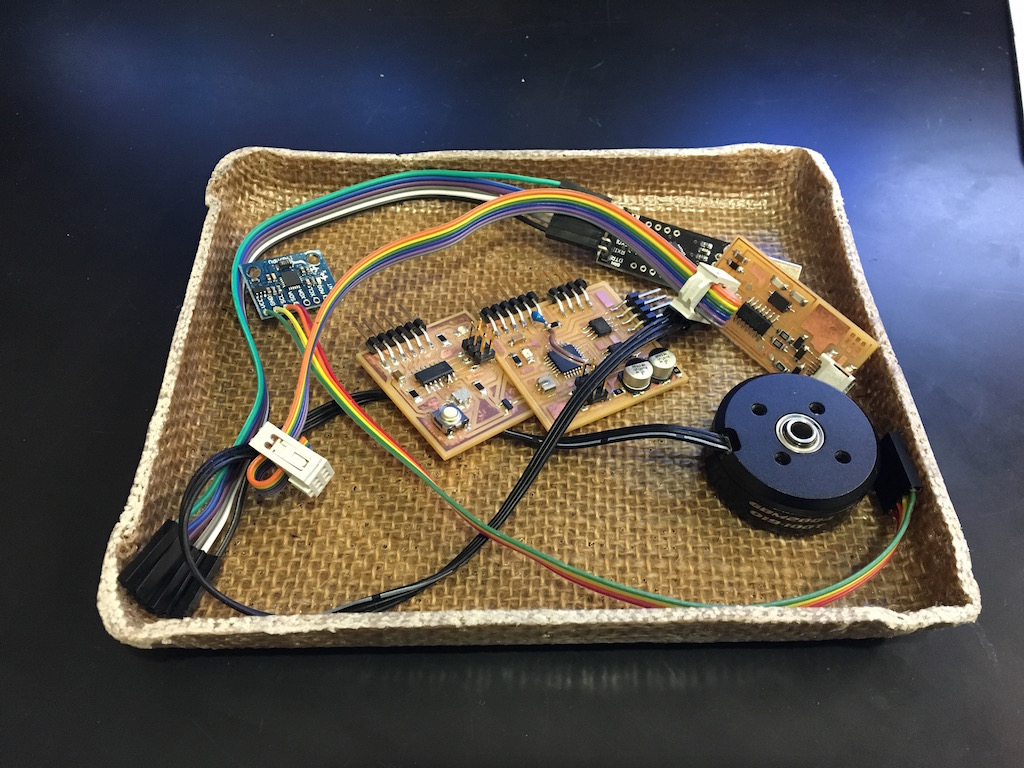

I used the box to keep all the electronic parts I made or bought.